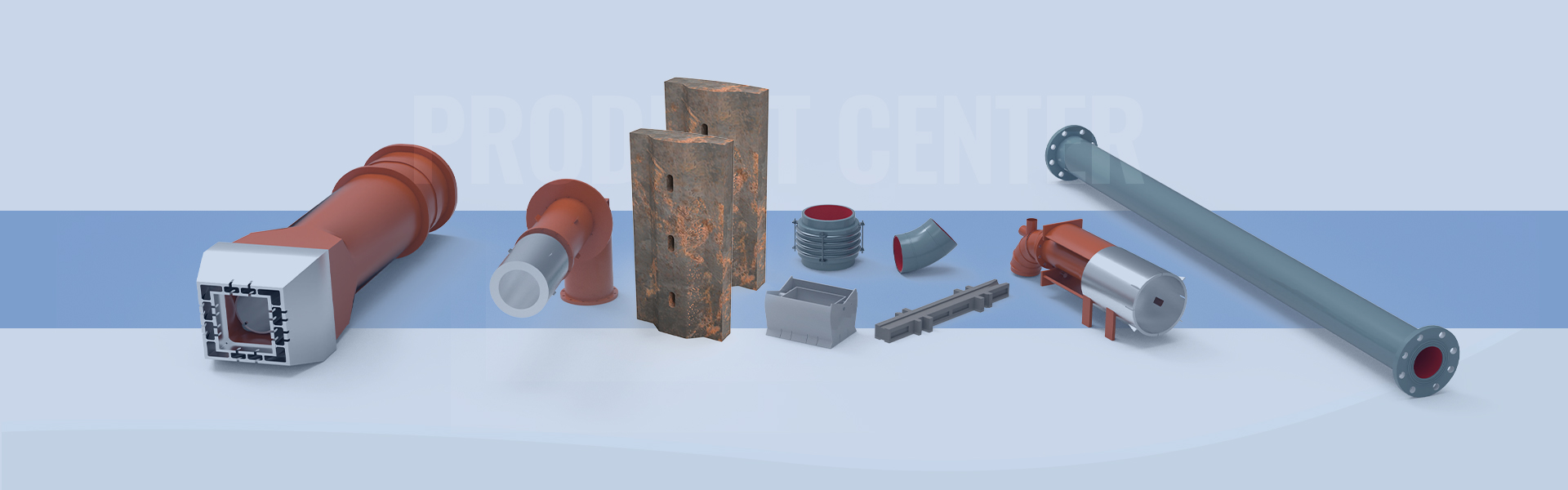

Model: Bimetallic composite lining plate for thermal power plants

Material: Working surface: High carbon and high chromium alloy Base surface: Carbon steel

Hardness: Rockwell hardness 58-60

Color: Painted exterior

Shape and size: Pipe (cylindrical)

Features: High wear resistance | Impact resistance | Service life exceeding 10 years